Product Description

About company:

HangZhou Shangyang Trading Co., Ltd. is a foreign trade technology enterprise focusing on providing air compressor products. The company has obvious advantages in the whole industry in terms of technical strength, business communication ability and quality control.

The company’s products mainly include air compressor, welding machine, cleaning machine, water pump, motor, etc., sold to more than 80 countries and regions around the world; And long-term for Europe, North and South America and other CHINAMFG brands and end sellers to provide high-quality air compressor products; The cooperation with these customers enables the company’s products to meet the technical and quality requirements of the mainstream markets in Europe and America.

Features Of YC-series Products

YC single-phase capacitor-start asynchronous motor series Is totally enclosed fan-cooled type. The starting torque of motors Is 2-3 times as rated torque. The motors have excellent performance such as low In noise, low In temperature-rise high. In overloading capacity and convenient maintain. It is widely application In all types of small machine tools, compressors, pumps, refrigerators and the equipment which need bigger starting torque etc. They are wonderful utilities for family workshop where only single-phase power are available. This series adopts class B insulation,IP44 degree of protection and IC0141 method of cooling.

Technical Data Of YC Series

| Model | Power (kw) | Speed (r/min) | Current (A) | Voltage (v) | EFF (%) | P.F. CosΦ | LRT RLT | BDT RLT | LRA RLA | Noise LodB(A) | Weight(kg) |

| YC711-2 | 0.18 | 2800 | 1.9 | 220 | 60 | 0.72 | 3 | 1.8 | 12 | 70 | 9.5 |

| YC712-2 | 0.25 | 2800 | 2.4 | 220 | 64 | 0.74 | 3 | 1.8 | 15 | 70 | 10 |

| YC711-4 | 0.12 | 1400 | 1.9 | 220 | 50 | 0.58 | 3 | 1.8 | 9 | 65 | 9.5 |

| YC712-4 | 0.18 | 1400 | 2.5 | 220 | 53 | 0.62 | 2.8 | 1.8 | 12 | 65 | 10 |

| YC801-2 | 0.37 | 2800 | 3.4 | 220 | 65 | 0.77 | 2.8 | 1.8 | 21 | 75 | 13.5 |

| YC802-2 | 0.55 | 2800 | 4.7 | 220 | 68 | 0.79 | 2.8 | 1.8 | 29 | 75 | 14.5 |

| YC801-4 | 0.25 | 1400 | 3.1 | 220 | 58 | 0.63 | 2.8 | i.a | 15 | 65 | 13.5 |

| YC802-4 | 0.37 | 1400 | 4.2 | 220 | 62 | 0.64 | 2.5 | 1.8 | 21 | 70 | 14.5 |

| YC90S-2 | 0.75 | 2800 | 5.9 | 220 | 70 | 0.8 | 2.5 | 1.8 | 37 | 75 | 22 |

| YC90L-2 | 1.1 | 2800 | 8.7 | 220 | 72 | 0.8 | 2.5 | 1.8 | 60 | 78 | 21 |

| YC90S-4 | 0.55 | 1400 | 5.5 | 220 | 66 | 0.69 | 2.5 | 1.8 | 29 | 70 | 22 |

| YC90L-4 | 0.75 | 1400 | 6.9 | 220 | 68 | 0.73 | 2.5 | 1.8 | 37 | 70 | 21 |

| YC100L1-2 | 1.5 | 2800 | 11.4 | 220 | 74 | 0.81 | 2.5 | 1.8 | 80 | 83 | 31 |

| YC100L2-2 | 2.2 | 2800 | 16.5 | 220 | 75 | 0.81 | 2.2 | 1.8 | 120 | 83 | 33 |

| YC100L1-4 | 1.1 | 1400 | 9.5 | 220 | 71 | 0.74 | 2.5 | 1.8 | 60 | 73 | 31 |

| YC100L2-4 | 1.5 | 1400 | 12.5 | 220 | 73 | 0.75 | 2.5 | 1.8 | 80 | 78 | 32 |

| YC112M-2 | 3 | 2800 | 21.9 | 220 | 76 | 0.82 | 2.2 | 1.8 | 150 | 87 | 46 |

| YC112M-4 | 2.2 | 1400 | 17.8 | 220 | 74 | 0.76 | 2.2 | 1.8 | 120 | 78 | 40 |

Service:

| before sales | 1.24 hours online service . 2.Any inquiries will be replied within 12 hours. 3.Offer professional machine details and information. 4.Technology knowledge share . |

| on sale |

1.Protect the client payment security . more better. |

| after sales |

1.Fast delivery and test and adjust machine working well before delivery. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Operating Speed: | High Speed |

|---|---|

| Number of Stator: | Single-Phase |

| Species: | Ml Series |

| Rotor Structure: | Winding Type |

| Casing Protection: | Protection Type |

| Number of Poles: | 2 |

| Samples: |

US$ 35/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can Single-Phase Motors be Used for Powering Air Compressors?

Yes, single-phase motors can be used for powering air compressors, but there are certain considerations to keep in mind when choosing a single-phase motor for this application.

When selecting a motor for an air compressor, it’s important to consider the power requirements of the compressor, including the horsepower (HP) rating and the desired operating pressure. Single-phase motors are available in a range of HP ratings, and it’s crucial to choose a motor that can provide sufficient power to meet the demands of the air compressor.

Additionally, the starting torque requirements of the air compressor should be taken into account. Air compressors typically require high starting torque to overcome the initial resistance and start the compression process. Single-phase motors generally have lower starting torque compared to three-phase motors, so it’s important to ensure that the selected single-phase motor can provide adequate starting torque for the specific air compressor.

Furthermore, the efficiency of the motor should be considered, as it can impact the overall performance and energy consumption of the air compressor. While single-phase motors are generally less efficient than three-phase motors, there are high-efficiency single-phase motors available in the market that can help mitigate this issue.

Another factor to consider is the duty cycle of the air compressor. If the compressor will be running continuously or for extended periods, it’s important to ensure that the chosen single-phase motor is designed for continuous duty and can handle the heat generated during prolonged operation.

It’s also worth noting that single-phase motors may require additional components such as capacitors or starting devices to improve their starting performance. These components help provide the necessary phase shift and boost the starting torque of the motor.

In summary, single-phase motors can be used for powering air compressors, but careful consideration should be given to factors such as power requirements, starting torque, efficiency, duty cycle, and the need for additional components. It’s recommended to consult with a motor manufacturer or an expert in the field to ensure the selected single-phase motor is suitable for the specific air compressor application.

How do you determine the horsepower (HP) rating for a single-phase motor?

To determine the horsepower (HP) rating for a single-phase motor, you need to consider several factors and perform calculations based on motor specifications. Here is a step-by-step process to determine the HP rating:

- Identify motor specifications: Start by gathering information about the motor, including its voltage rating, current rating, power factor, and efficiency. These specifications are typically provided by the motor manufacturer and can be found on the motor nameplate.

- Calculate power input: The power input to the motor can be calculated using the formula:

Power input (in watts) = Voltage (in volts) x Current (in amps) x Power factor

- Convert power input to horsepower: Since 1 horsepower is equal to 746 watts, you can convert the power input to horsepower using the formula:

Horsepower (HP) = Power input (in watts) / 746

- Consider motor efficiency: If the motor efficiency is provided, multiply the calculated horsepower by the efficiency to obtain the rated horsepower. For example, if the motor efficiency is 0.9 (or 90%), the rated horsepower would be:

Rated Horsepower = Horsepower (HP) x Efficiency

By following these steps and considering the motor specifications, you can determine the horsepower rating for a single-phase motor.

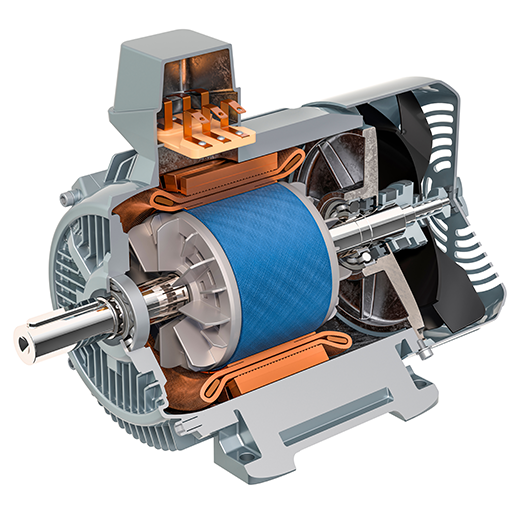

What are the main components of a single-phase motor, and how do they function?

A single-phase motor consists of several key components that work together to generate rotational motion. Each component plays a crucial role in the motor’s operation. Let’s explore the main components of a single-phase motor and how they function:

- Stator: The stator is the stationary part of the motor and is responsible for producing a rotating magnetic field. In a single-phase motor, the stator contains a main winding or coil, which is energized by the single-phase power supply. When current flows through the winding, it generates a magnetic field that interacts with the rotor to produce motion.

- Rotor: The rotor is the rotating component of the motor. It is typically made of laminated iron cores and is located inside the stator. The rotor interacts with the rotating magnetic field generated by the stator, causing the rotor to rotate. In a single-phase motor, the rotor does not have its own magnetic field and relies on the action of the stator to induce the rotational motion.

- Starting Mechanism: Single-phase motors require specific starting mechanisms to overcome the absence of a rotating magnetic field during startup. These mechanisms are necessary to initiate rotation. Common starting mechanisms in single-phase motors include auxiliary windings and centrifugal switches or capacitors. The auxiliary winding, also known as the starting winding, creates an additional magnetic field during startup, providing the initial torque required to overcome inertia. Once the motor reaches a certain speed, centrifugal switches or capacitors disconnect or deactivate the starting mechanisms to allow the motor to run efficiently.

- Capacitor: Capacitors are often used in single-phase motors to provide the necessary phase shift to create a rotating magnetic field. Capacitors store electrical energy and release it in a controlled manner, helping to create the necessary phase difference between the main winding and the auxiliary winding. This phase shift enables the motor to produce the rotating magnetic field required for rotation.

- Centrifugal Switch: Some single-phase motors incorporate centrifugal switches in their starting mechanisms. These switches are typically attached to the motor shaft and operate based on centrifugal force. During startup, the centrifugal switch remains closed, allowing the auxiliary winding and starting mechanisms to be active. As the motor reaches a predetermined speed, the centrifugal force causes the switch to open, disconnecting the auxiliary winding and starting mechanisms. This ensures that the motor operates efficiently without unnecessary torque variations.

- Bearings: Bearings are used to support the rotor and allow it to rotate smoothly within the motor. The bearings minimize friction and provide stability for the rotating components. Proper lubrication and maintenance of the bearings are essential for the motor’s long-term performance and reliability.

- Enclosure: The motor enclosure provides protection and insulation for the internal components. It helps prevent dust, moisture, and other contaminants from entering the motor, which could impair its operation. The enclosure also contributes to the motor’s overall safety by isolating the electrical components from external contact.

Each component of a single-phase motor plays a vital role in converting electrical energy into mechanical motion. The stator generates the rotating magnetic field, while the rotor interacts with this field to produce rotation. The starting mechanisms, such as auxiliary windings, capacitors, and centrifugal switches, ensure that the motor starts reliably and efficiently. Bearings support the rotating components, and the enclosure provides protection and insulation for the motor’s internal parts.

Understanding the function of these components helps in troubleshooting motor issues, performing maintenance, and selecting the appropriate motor for specific applications.

editor by CX 2024-04-19